This post is part of G2's 2024 technology trends series. Read more about G2’s perspective on digital transformation trends in an introduction from Chris Voce, VP, market research, and additional coverage on trends identified by G2’s analysts.

Manufacturers will increase CAD and CPQ integration to enhance customer experience

Prediction

In 2024, G2 predicts a growth in the integration of computer-aided design (CAD) software with configure, price, quote (CPQ) solutions to automate the creation of CAD drawings, allowing users to configure digital models of products based on customer specifications.

Industries where product design and customization are essential, such as manufacturing, engineering, and construction, will increasingly integrate CAD and CPQ software solutions to varying degrees depending on their requirements and technological advancements.

What are CAD and CPQ software?

Computer-aided design (CAD) software is used by engineers, architects, and designers to create detailed 2D and 3D models of objects, buildings, or mechanical parts.

Configure, price, quote (CPQ) software helps companies accurately define the cost of goods, configure complex products or services according to customer requirements, and generate quotes for customers quickly and accurately.

As the manufacturing sector evolves, the integration and automation of CAD is only logical. Combining CAD with CPQ software is a time-saver for organizations, benefiting various departments like engineering, production, and sales.

Let’s closely examine how CAD integration and automation will help drive productivity gains and efficiency.

CPQ-CAD integration will help manufacturers effortlessly navigate product complexities

Products that are intricately designed and often tailored to specific customer requirements range from industrial equipment to automotive and aerospace machinery to furniture, electronics, etc.

Producing and managing these products efficiently can be challenging. This is due to the availability of a wide range of customizable features, various possible configurations, and interdependencies of features.

To address this, many manufacturing companies connect their CAD software with CPQ software or product configurators, which allows them to automatically generate a complete CAD model based on the selected configuration options and values. The integration also helps companies calculate product costs, generate quotes, and facilitate sales.

80%

of employees reported that automation gave them more time to deepen relationships with customers and other stakeholders, take on challenging new projects, and learn new skills.

Source: Harvard Business Review

Connecting CAD and CPQ systems also helps automate the transfer of product configuration data from CAD to CPQ, eliminating the need for manual data entry. This facilitates the automated generation of quotes, allowing sales representatives to address customer inquiries promptly.

Unraveling CAD and CPQ insights from G2 Data

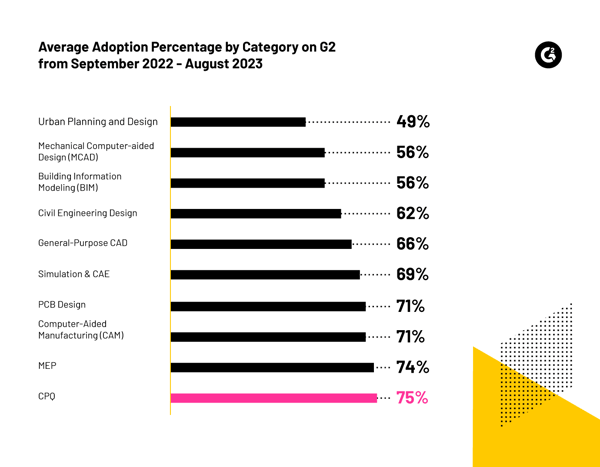

The chart below illustrates the average adoption percentages of CPQ and the CAD software categories on G2, as determined by user reviews.

Adoption percentage here refers to the average rate at which users or organizations adopt or use a particular product or service within a specific category. The average adoption percentage is calculated by taking the average of all products’ adoption data across companies within a category.

The adoption rate of CPQ software is higher than all the CAD design tools. This can be attributed to the flexibility and the level of automation the tool offers. It empowers salespeople to provide clients with customized solutions while offering insights and analytics to drive better decision-making.

CPQ software can seamlessly integrate with CAD tools, enabling smooth data flow and processes throughout the organization. This integration between CAD and CPQ enhances alignment between product design and sales processes, resulting in quicker, more precise quotations, enhanced collaboration, and an improved customer experience.

CAD-CPQ integrations: unlock the full potential

Manufacturers harnessing the power of CAD and CPQ integration will benefit beyond the capabilities of CPQ software alone.

CAD-CPQ integration injects a human touch into the product configuration and quoting processes. It’s like having a seasoned sales expert by the side, ensuring that the customization choices align seamlessly with the company's policies and pricing guidelines, which happens in real time.

CPQ software goes further by automating the quote generation process, saving hours of mundane administrative work.

Additionally, it's akin to having a vigilant assistant who verifies that the product ideas are not just accurate but also entirely feasible, guaranteeing that customers receive precisely what they desire.

This makes the entire experience remarkably smoother, virtually error-free, and uniquely tailored to customers’ preferences. These advanced capabilities optimize the design and sales processes and elevate the overall experience for the company and its valued customers.

Ultimately, it's about combining technologies to create a smoother, more personalized design and sales journey for all involved.

The ongoing use of siloed tools and disparate processes acts as a roadblock, impeding both growth and the improvement of manufacturing operations. Learn how integrating PLM, QMS, and ERP can solve these challenges.

Edited by Shanti S Nair

by Anindita Sengupta

by Anindita Sengupta

by Anindita Sengupta

by Anindita Sengupta

by Anindita Sengupta

by Anindita Sengupta